Identifying Faults

When testing low-voltage wiring, it is important first to identify any faults that may be present. One common issue is a short circuit, which occurs when a wire carrying current comes into contact with another wire or a conductive surface. This can cause a blown fuse or a tripped breaker. Another common issue is a loose or corroded connection, which can cause intermittent or complete loss of power.

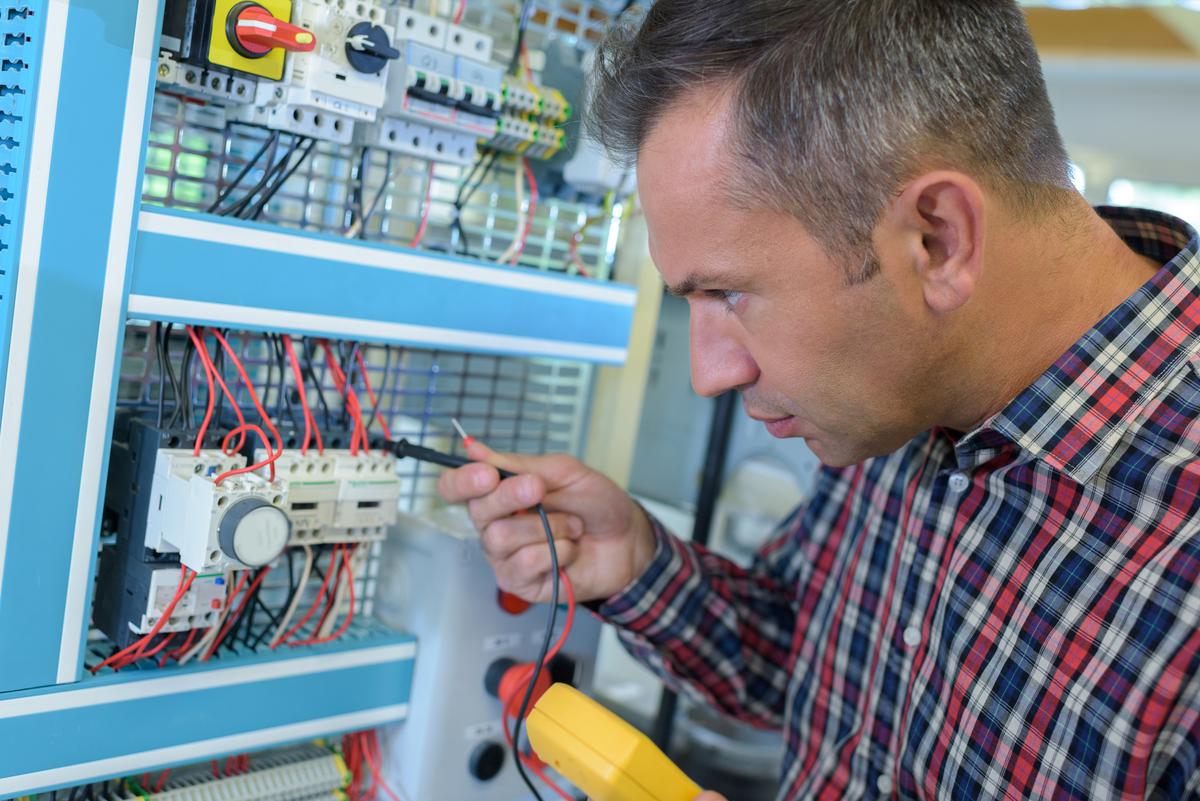

To identify faults, use a multimeter to test for continuity between each wire and ground. If there is continuity, this indicates a short circuit. If there is no continuity but a low-voltage reading, this may indicate a loose or corroded connection. Check all connections and wires for signs of damage or corrosion, and repair or replace them as necessary.

Repairing Connections

If a loose or corroded connection is identified, it is important to repair it as soon as possible to prevent further damage or loss of power. Begin by turning off power to the affected circuit and removing any damaged or corroded wires or connections.

Clean any corrosion from the affected area using a wire brush or sandpaper, and apply a small amount of electrical contact cleaner to the area. Replace any damaged wires or connections with new ones, making sure to tighten all screws and connections securely.

After repairing the connection, test the circuit again using a multimeter to ensure that the voltage reading is within the expected range. If the voltage reading is still low or there is no continuity, continue to troubleshoot the circuit until the issue is resolved.

Best Practices for Maintenance

Maintaining low-voltage wiring is essential to ensure its proper functioning. Here are some best practices for maintenance that you should follow.

1. Regular Inspection

It is important to inspect low-voltage wiring regularly for any physical damage, such as cuts, abrasions, or exposed wires. You should also check for any signs of overheating or discoloration, which could indicate a problem. Inspect the wiring thoroughly and look for any signs of wear and tear.

2. Keep Wiring Clean

Dirt and dust can accumulate on the wires over time, which can cause them to malfunction. To prevent this, keep the wiring clean by wiping it down with a dry cloth regularly. Avoid using water or any other liquid to clean the wiring, as this could cause damage.

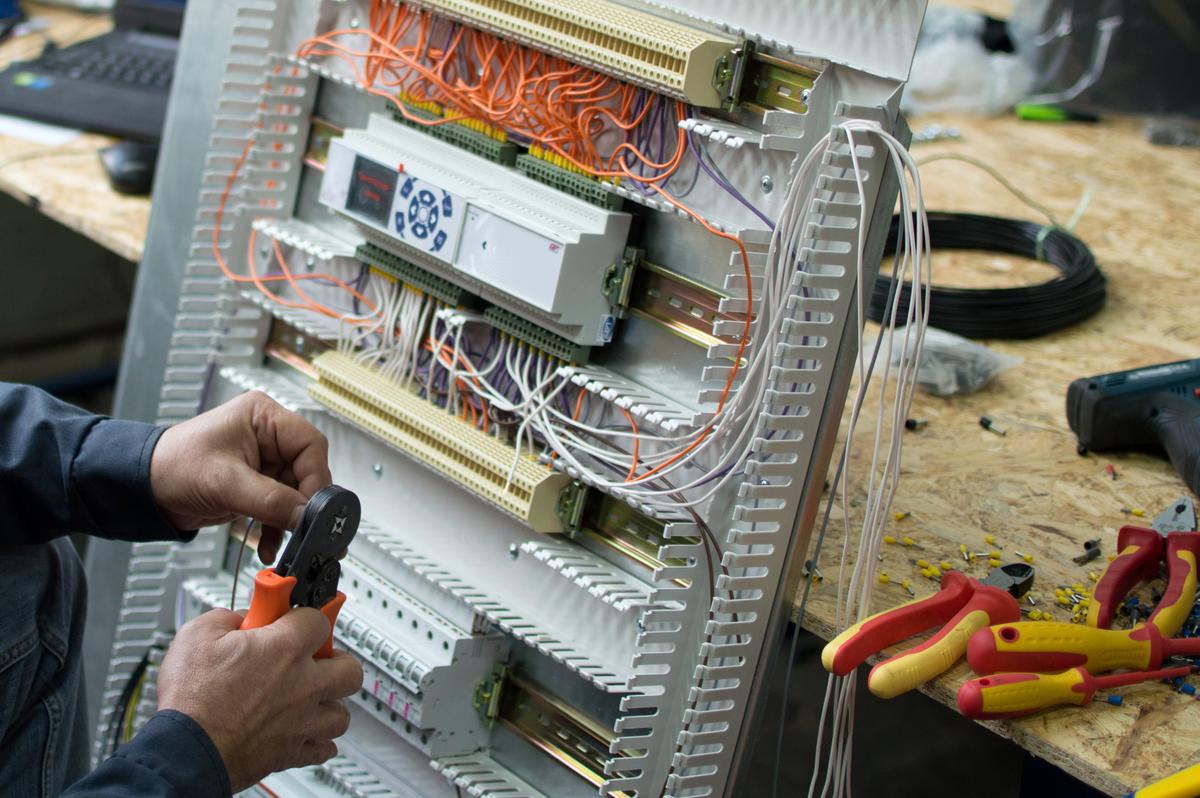

3. Use Proper Tools

Always use the right tools when working with low-voltage wiring. This includes wire strippers, crimpers, and cutters. Using the wrong tools can damage the wiring, which can lead to malfunctions or even electrical fires.

4. Follow Safety Procedures

When working with low-voltage wiring, always follow safety procedures to prevent accidents. This includes wearing protective gear, such as gloves and safety glasses. Ensure the power is turned off before working on the wiring, and never touch it with wet hands.

By following these best practices for maintenance, you can ensure that your low-voltage wiring functions properly and safely.

comments